SHARING OUR VISION

ENOR LED Screens are Backed By An experienced r&D team

We have the technology, we have the know-how, and we have rich experience in the LED screen manufacturing process.

LED video panels OEM Supported, anything you need about Full-color LED screens, you can come to us.

Email:info@enorled.com

SMT Processing Line

DIP LED module producing process

LED module spray treatment

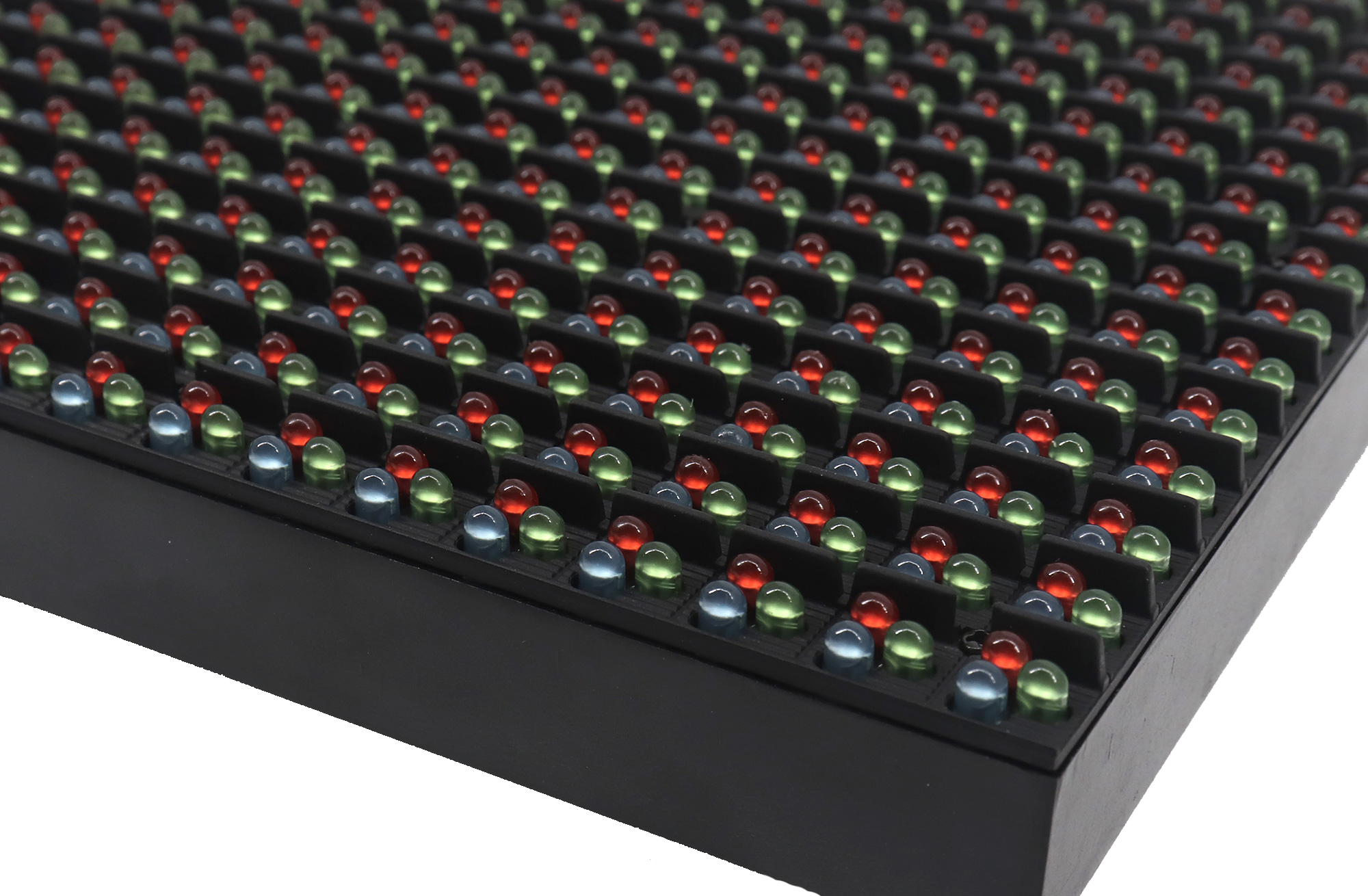

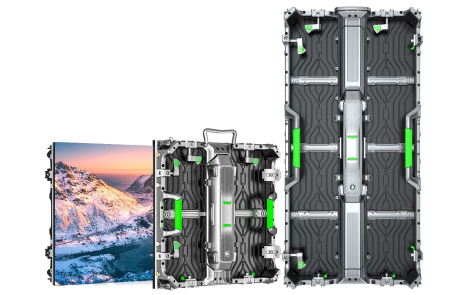

LED Modules/LED Tiles

LED Module under test

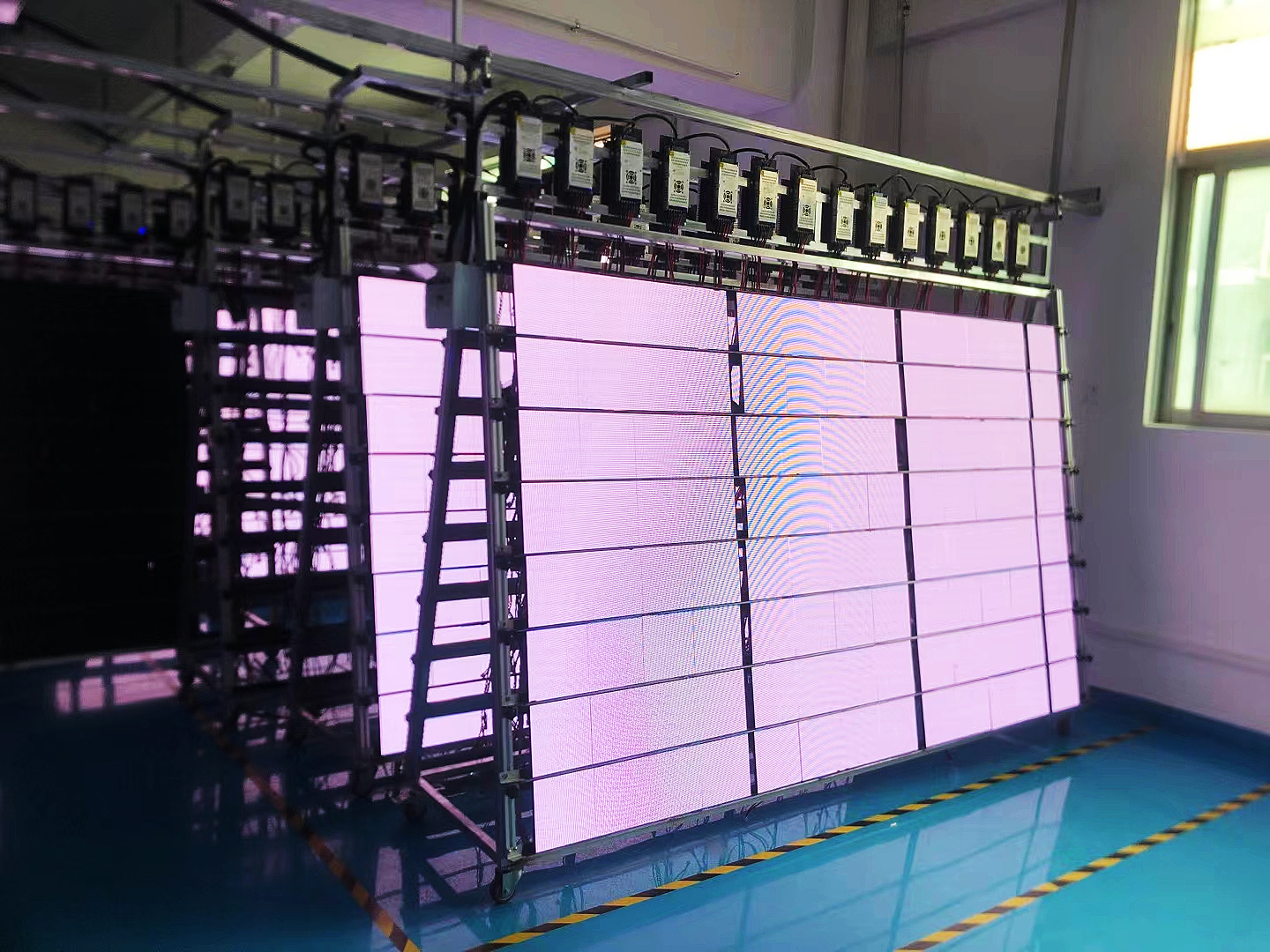

LED panels aging test

Transparent LED video wall test

ENOR LED panels Plywood Box Packages

Aging test areas for LED displays

Football stadium LED wall

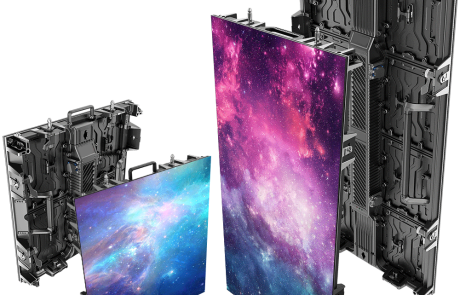

ENOR Outdoor LED Video Wall Panels

best outdoor led screen p10

Outdoor LED screens

Outdoor Advertising Screens:P4,P5,P6,P8,P10,P16.etc

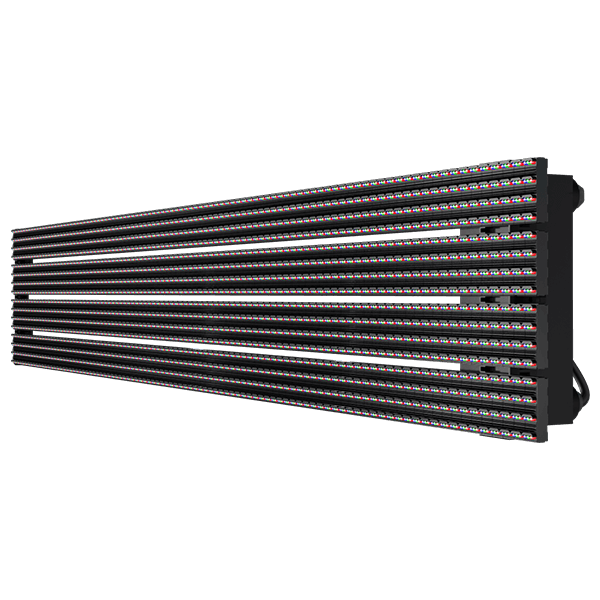

Both SMD Screen and DIP LED Screens.

Introduction to LED Display Workshop Production Machines

In an LED display workshop, various production machines are used to manufacture high-quality LED displays. These machines play crucial roles in different stages of the production process, ensuring the efficiency and reliability of the LED display manufacturing.

LED Testing Equipment

LED testing equipment is utilized to assess the performance of LED raw materials, ensuring that only high-quality components are used in the production process.

DIP Insertion Machine

The DIP insertion machine is specifically designed for producing outdoor DIP large screens. It is commonly used for manufacturing DIP screens with different pixel pitches such as P10 and P16, catering to various display requirements.

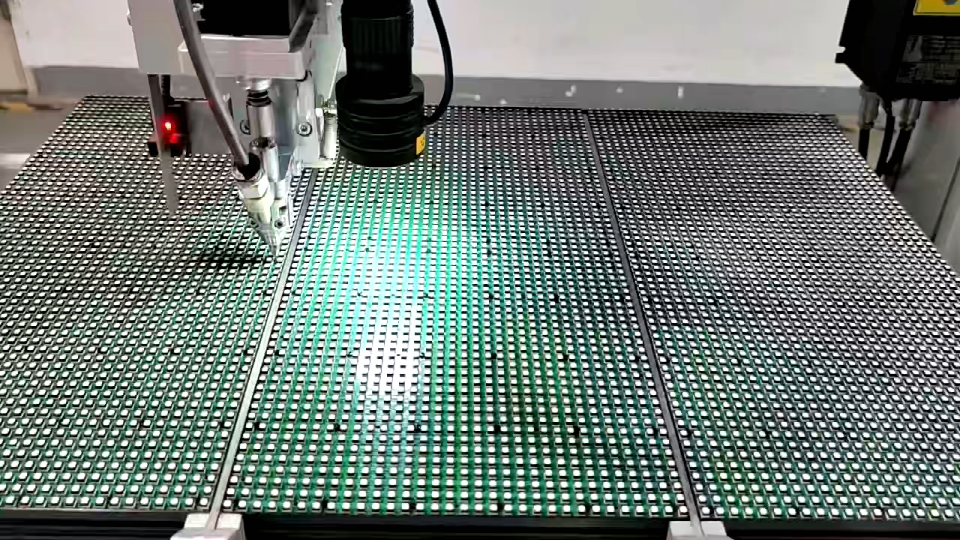

SMT Machine

The SMT (Surface Mount Technology) placement machine is employed for the precise placement of SMD (Surface Mount Device) modules and chips, contributing to the assembly of LED display modules.

Reflow Soldering

Reflow soldering equipment is responsible for soldering LED modules, ensuring secure connections and optimal functionality of the assembled components.

Painting Equipment

Painting equipment is utilized to apply protective coatings on LED modules, serving the purpose of dustproofing, waterproofing, and corrosion resistance.

Quality Inspection Devices

Quality Inspection Devices: Quality inspection devices are essential for ensuring the flawless operation of LED screens. These devices conduct various tests including brightness, grayscale, color, simulated transportation, and waterproofing tests to validate the performance and durability of the LED displays.

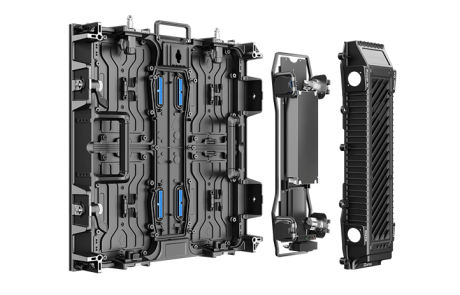

About ENOR LED Display Factory

ENOR Display Factory is an experienced LED screen manufacturer known for its stringent incoming material inspection, strict product quality control, high production capacity, dust-free workshops, and rigorous testing processes. As a reputable producer, ENOR maintains a commitment to delivering high-quality LED display products with a focus on precision and reliability.We are good at producing indoor led screens,outdoor advertising led panels,DIP video walls,rental led displays.etc

I hope this information provides a comprehensive overview of the production machines commonly found in an LED display workshop, as well as an introduction to ENOR Display Factory’s expertise in LED screen production.

Our Production Lines

Indoor&Outdoor Advertising LED displays,Rental LED Screens,All-in-one Full Color LED Panels.etc

Email:info@enorled.com